Nitrile is a third-generation disposable glove substance that was first developed in the 1990s. German chemists Erich Konrad and Eduard Tschunkur patented nitrile butadiene rubber (NBR) in 1934, and commercial development began in earnest in the 1930s for tire manufacturing and rubber seals. After developing the first 100 percent nitrile disposable glove in 1991, Neil Tillotson and Luc DeBecker were awarded a patent for nitrile exam glove technology.

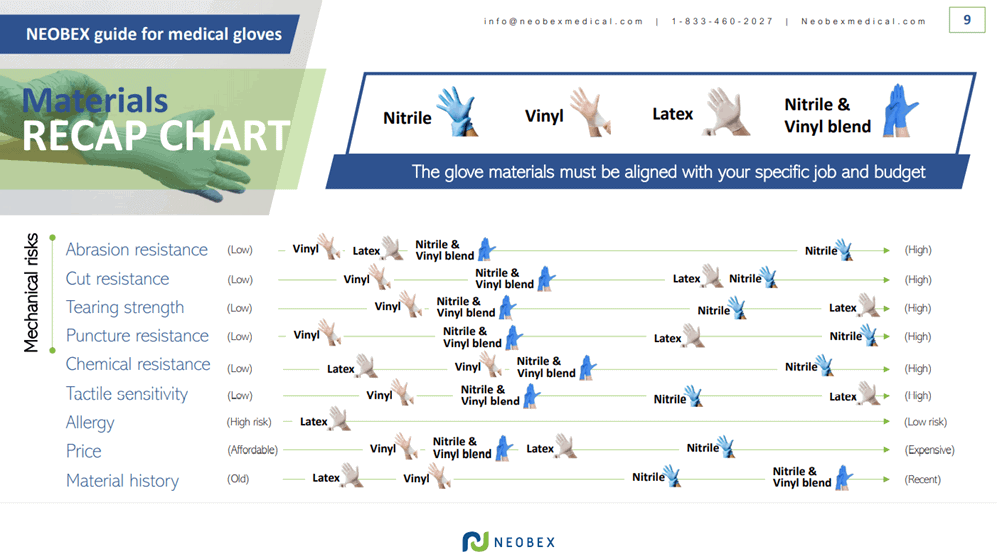

Nitrile gloves were late to catch on in the medical community, but they quickly became the “Next Big Thing” in the hand protection sector at the expense of latex. Nitrile is currently the most widely recommended disposable glove. The material is stronger than latex or vinyl, with a latex-like fit, feel, and comfort. Nitrile has three times the puncture resistance of latex, as well as three times the abrasion and chemical resistance. It is recommended for working with 3/4 of common chemicals on the market. Mineral oils, vegetable oils, grease, gasoline, diesel fuel, and a variety of acids are all resisted by nitrile.

Nitrile does not aggravate latex allergies because it is free of organic latex proteins. This is not only important for latex-sensitive individuals, but also for consumers who come into close physical contact with the general public, such as medical and dental practitioners, security officers, tattoo artists, and salon employees. Nitrile gloves are not only widely adopted in the medical industry but also in automotive, construction, janitorial, plumbing, paint shop, chemical, and industrial applications. They’re also ideal for use in the food processing industry.

Nitrile gloves are available in two grades: industrial and exam. As nitrile gloves warm up from your body heat, they conform to your hands for a more uniform and comfortable fit. The cost of petroleum determines the price. Nitrile gloves are more costly than other fabrics, but they are more durable and suitable for long-term use. The thickness of many industrial-grade nitrile gloves is increased to better withstand more demanding applications. Nitrile gloves often last longer than natural latex rubber gloves.